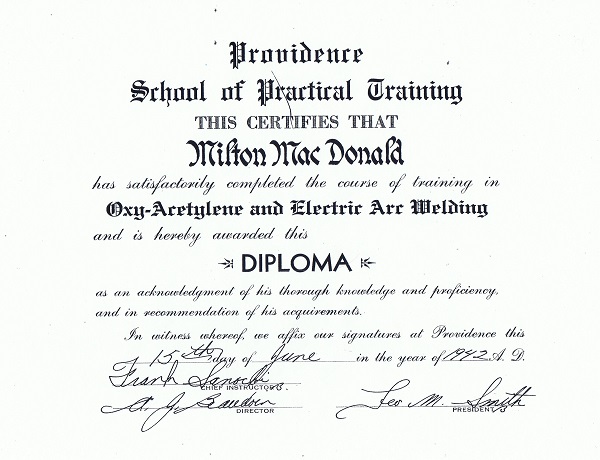

Training:

- In June of 1942, Milton completed the training in Oxy-Acetyline and Electric Arc Welding at the Providence School of Practical Training.

Record of Employment: 1933-1945

- 7-1933 to 7-1942 Arkwright Finishing Company, Fiskeville, R.I. Calender Operator (operating and repairing machine)

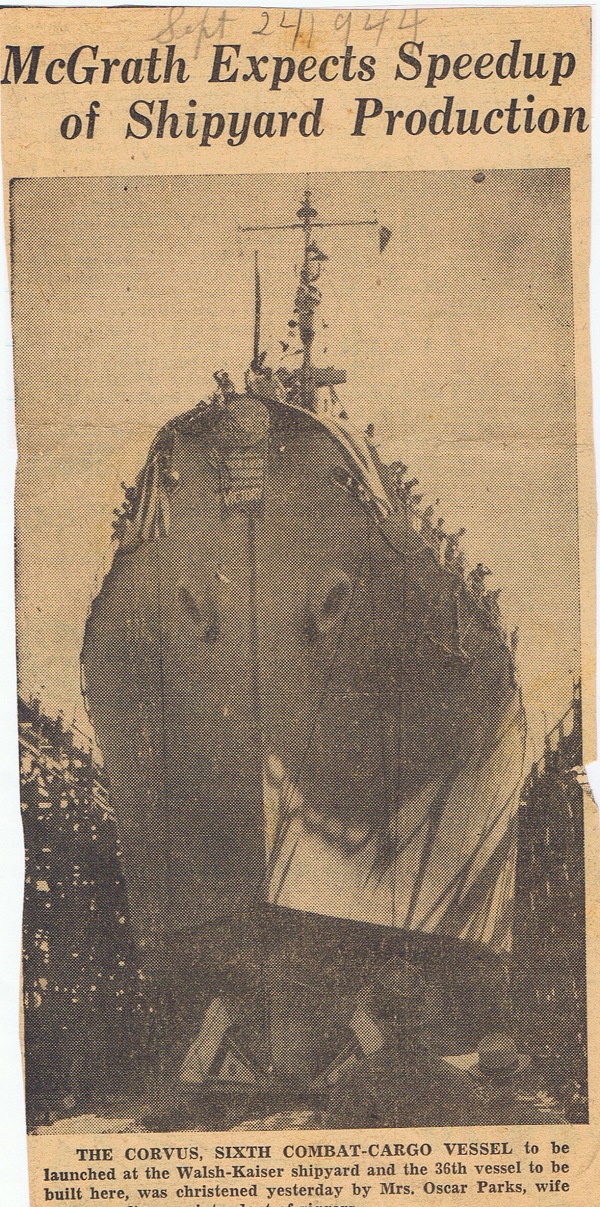

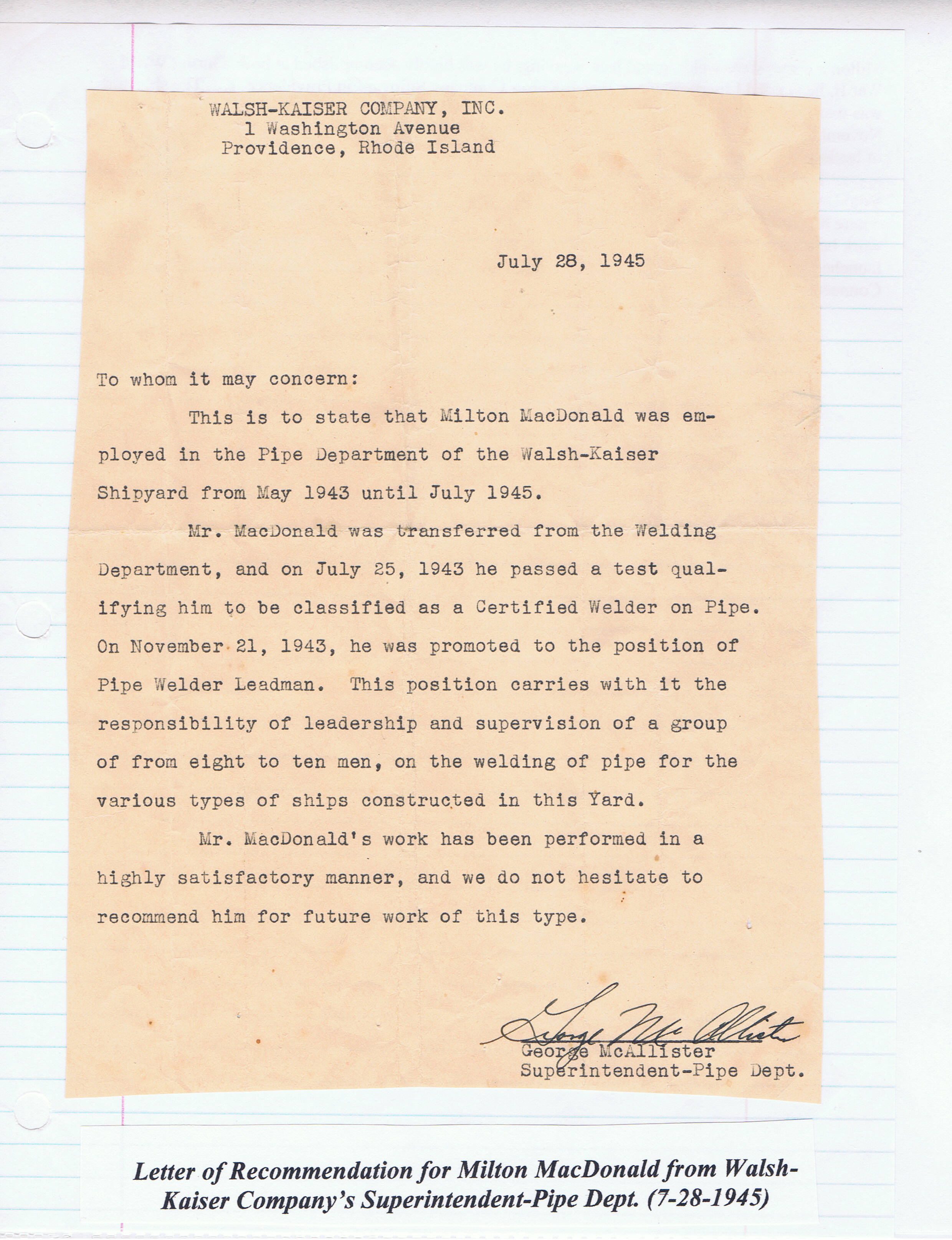

- 7-1942 to 7-1945 Rheem Mfg Co. changed to Walsh-Kaiser, Providence. R.I. Shipbuilding Welder 1st class, Welding in all positions

- (“Walsh-Kaiser Co., Inc. was a shipyard in both Cranston and Providence, R.I. It was built during World War II and financed by the Maritime Commission as part of the country’s Emergency Shipbuilding Program. It was originally operated by Rheem Mfg., a company with no previous shipbuilding expertise. When Rheem had difficulty managing the yard, Kaiser Shipyards was retained to manage the operation. … The first ships that the yard produced were Liberty ships. After ten ships were completed, 21 frigates were built. After those ships were finished, 32 Combat Loaded Cargo Vessels were constructed and launched. In the three years that the yard was in operation, 63 ships were eventually launched and completed. ” Wikipedia, the free encyclopedia)

- At the end of World War II, the shipyard closed. Following is a letter of recommendation for Milton Earl from Walsh-Kaiser Company’s Superintendent. George McAllister.

In the year 1944: Multiple Employers

- In 1944, Milton was still working full-time as a welder at Walsh-Kaiser Co. Inc. as the war did not end until August of 1945. However, in 1944, he also reported some wages from (1) Riverpoint Lace Works, Inc. (825 Main Street, West Warwick, R.I.), (2) Nottingham Lace Works, Inc. (Coventry, R.I.), and (3) Bellamy Lace Works, Inc. (Coventry, R.I.). After the war, he would work full-time in the lace weaving business.

After the war: Lace Weaving Trade

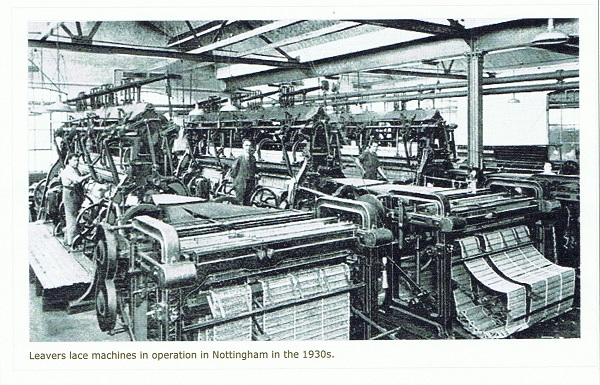

- After the war, Milton Earl began full-time work in lace weaving at a mill in Coventry. Apparently, there are various levels of skill, and a person starts employment as a threader and then continues on to be classified as a weaver. (Of course, the children were not allowed in the mill, but the couple of times that this web site author was in the mill was a fascinating experience. The machines were so loud and looked so complicated!) Milton became highly skilled and worked at a lace machine, that was as long as a large room. This was beautifully made lace that is no longer common today with the cheaply made and cheaply looking lace today.

- Below is a letter to Milton from the Amalgamated Lace Operatives of America.

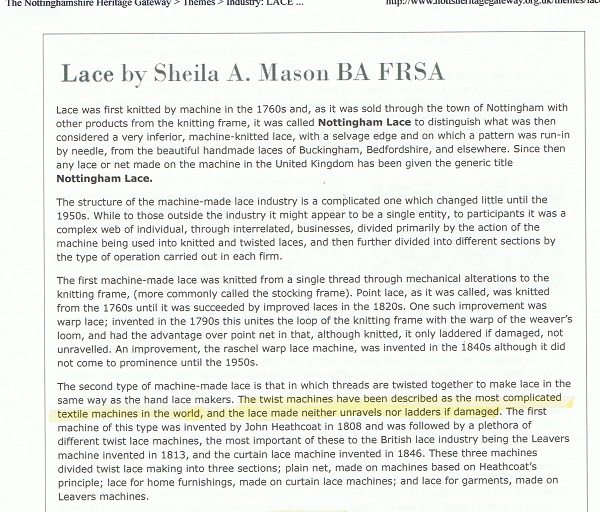

- Milton learned the lace weaving trade which usually took years for a person to master. Milton became highly skillled. Milton did not work in a large mill. His mill held around 8 to 10 lace weaving machines. The mill was located in a neighboring town of Coventry. The machines that he worked on were built in the 1890 or early 1900s in England and the machines were called Leavers Lace Machines. The machine was the entire length of the room. The lace was made in bands which were as long as the entire length of the machine. There were 20 -50 bands going around in a circle which made a big wide piece of lace with a few thousand threads coming through. By pulling a thread, the bands would come apart to the desired size. Although there were some machines where one person could run 8 or 10 machines, the machines that Milton worked on were one skilled person for one machine. Sheila A. Mason BA FRSA , author of “Lace”, wrote “The twist machines have been described as the most complicated textile machines in the world, and the lace made neither unravels nor ladders if damaged.”

- Additional information from Milton’s eldest son, Spencer, who also worked the lace weaving machines: “The Lever Lace machines were all made in England. The Rochelle machine which were introduced around 1958 were knitting machines. I do not know what country produced these machines. The Rochelle machine still worked lace, but were different because they could create a run in the lace. However, this machine did make the Lever machine somewhat obsolete because it took only one man to run it as compared to the eight men it took to run the Lever machine.”

- Web site author just found leaver lace machine on the internet. I googled Leaver Lace Machine and this machine looks like the machine that Dad worked in the 1950s. Web site author emailed her family members and the eldest sister responded “Sounds just like the machine when I went to see Dad-and looks like it too. One wonders how long it took Spen and Dad to thread such a large machine.”

- Unfortunately, this web site author does not have any pictures of the lace machine that Milton worked on. However, found on the internet (http://www.nottsheritagegateway.org.uk/themes/lace/lacegraphic.htm) was the following photo and information on Nottingham Lace which was first knitted by machine in the 1760s and named after the town of Nottingham, England, The machines that Milton, a highly skilled lace weaver, worked on in America were built in England around 1900.

- According to above article on “lace”, there was very little change in the industry for two-hundred years until the 1950s. When the lace weaving business was slowing down, the owners of the mill planned to lay off the employees. They asked Milton if he would stay on as the only employee and the mill would stay open until all this lace work business had finally come to a complete halt. The owner would let the other employees go. Milton, an honorable man, said all the workers were expecting reduced hours and it was not fair to the others if he alone was to keep his employment. Not long after, as expected, the mill closed.

- Milton, a skilled laborer and motivated worker, was actively seeking other employment and it was not long before he found other permanent employment. His work at the Lace Mill paid very well, and his next work in Groton, Connecticut at Electric Boat paid very well, also. In the few short weeks that he was not permanently employed, he took odd jobs here and there.

In the late 1950s: Returned to Welding Trade

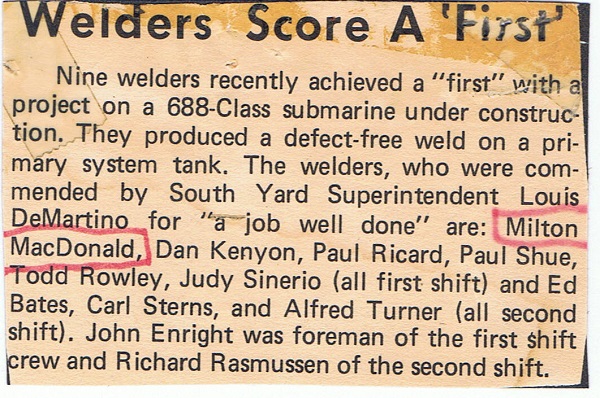

- When the lace weaving business slowed down, Milton Earl returned to welding. In the late 1950s, he began work at Electric Boat in Groton, Connecticut where he welded submarines.

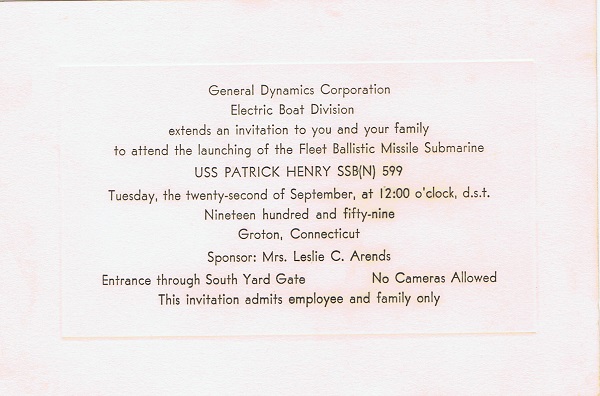

- At one of the launchings, the employee and family was invited.

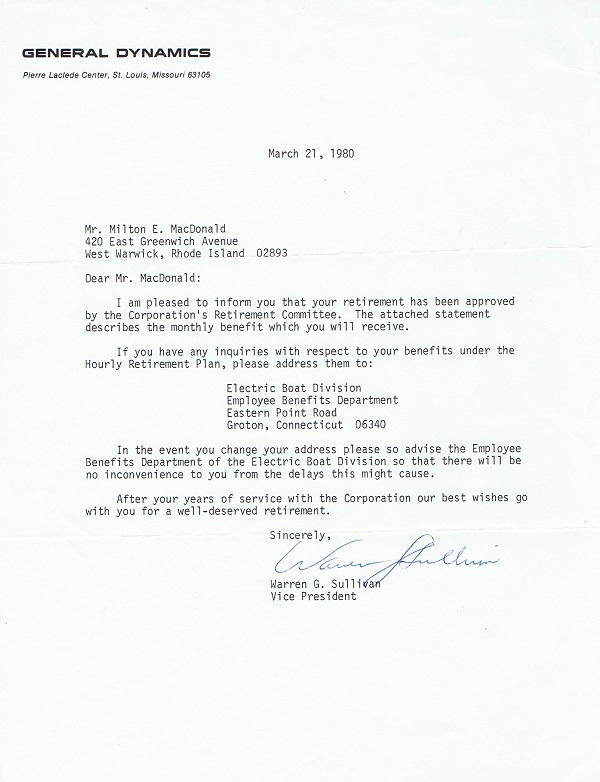

A “Well-Deserved Retirement” from full-time work: 1980

- Milton Earl retired from General Dynamics, Electric Boat Division in Groton, Connecticut in 1980 after twenty-five years of Service.

Milton Earl receiving retirement award from Representative of General Dynamics, Electric Boat Division

In Summary:

- Milton’s trades were welding and lace weaving; he was highly accomplished at both. During World War II, he welded Liberty Ships at Walsh-Kaiser Company Shipyard in Providence, Rhode Island. The shipyard was working around-the-clock building the ships that carried cargo and troops to Europe. On November 21, 1943, he was promoted to the position of Pipe Welder leadsman with the responsibility of leadership and supervision of a group of eight to ten men. After the war, he mastered the three-year apprenticeship in lace-weaving to become a highly skilled lace weaver. When the lace weaving business slowed down, Milton returned to welding. (Milton’s third daughter remembers her father telling her that a lace weaving machine from Germany took the place of eight men and that is when Milton returned to welding.)He went to General Dynamics where he welded submarines. The last few years he was an inspector charged with ensuring that the work being done by Electric Boat would be approved by the Navy allowing the submarine to be launched. He retired at welding-master level, from General Dynamics Electric Boat in Groton, Connecticut, in 1980.

Vaughn, Spencer, Walton, and MacDonald Press, Hemet, California 92544 Copyright © 2014 by Heather D. MacDonald

“MacDonald and Walton descendants, if you have any additional information on Milton MacDonald’s work history please add a comment to this web site and the web site author will add this to the site. Thanks!” (Contact Us-on upper right side of page)